Site Twins for Mining, Manufacturing, Recycling & Quarries

One platform, configured for your Site specific assets, processes and decisions.

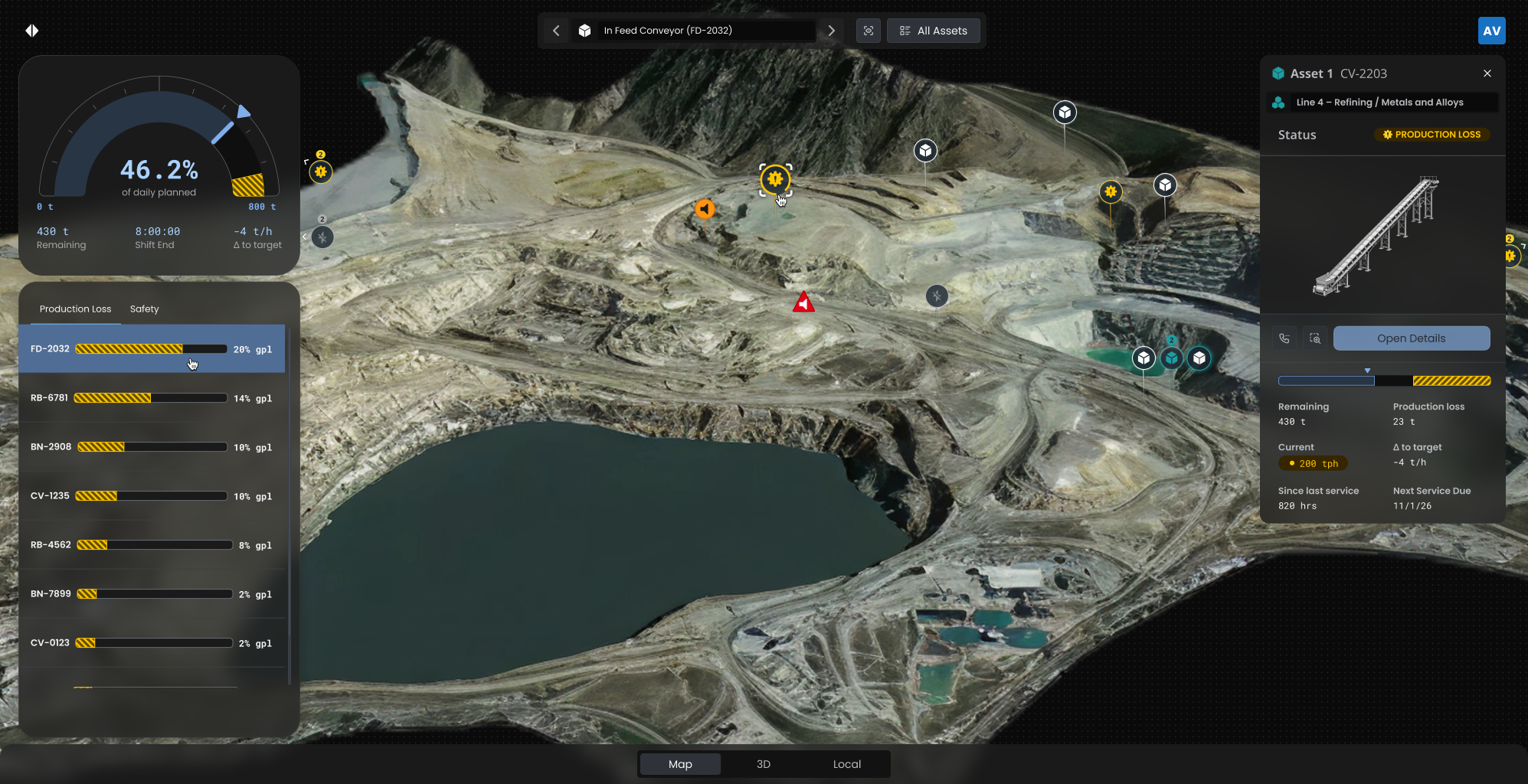

Mining Site Twin

Focus 1: short interval throughput optimization by identifying system-level constraints from pit/face to product stockpiles and aligning actions and plan changes across mining, processing & maintenance.

Focus 2: real time safety monitoring and automated notification/escalation by AI cameras in high risk (e.g. confined space), heavy / light vehicle and light vehicle / pedestrian zones.

Common first win: Mining & Processing collaborate in real time on grade control/ROM pads/crushing/rehandling and system throughput goes up with less rehandle.

Key connected systems & plans: OT Historian, EAM, Process Plan, Mining Plan, Safety, Fleet

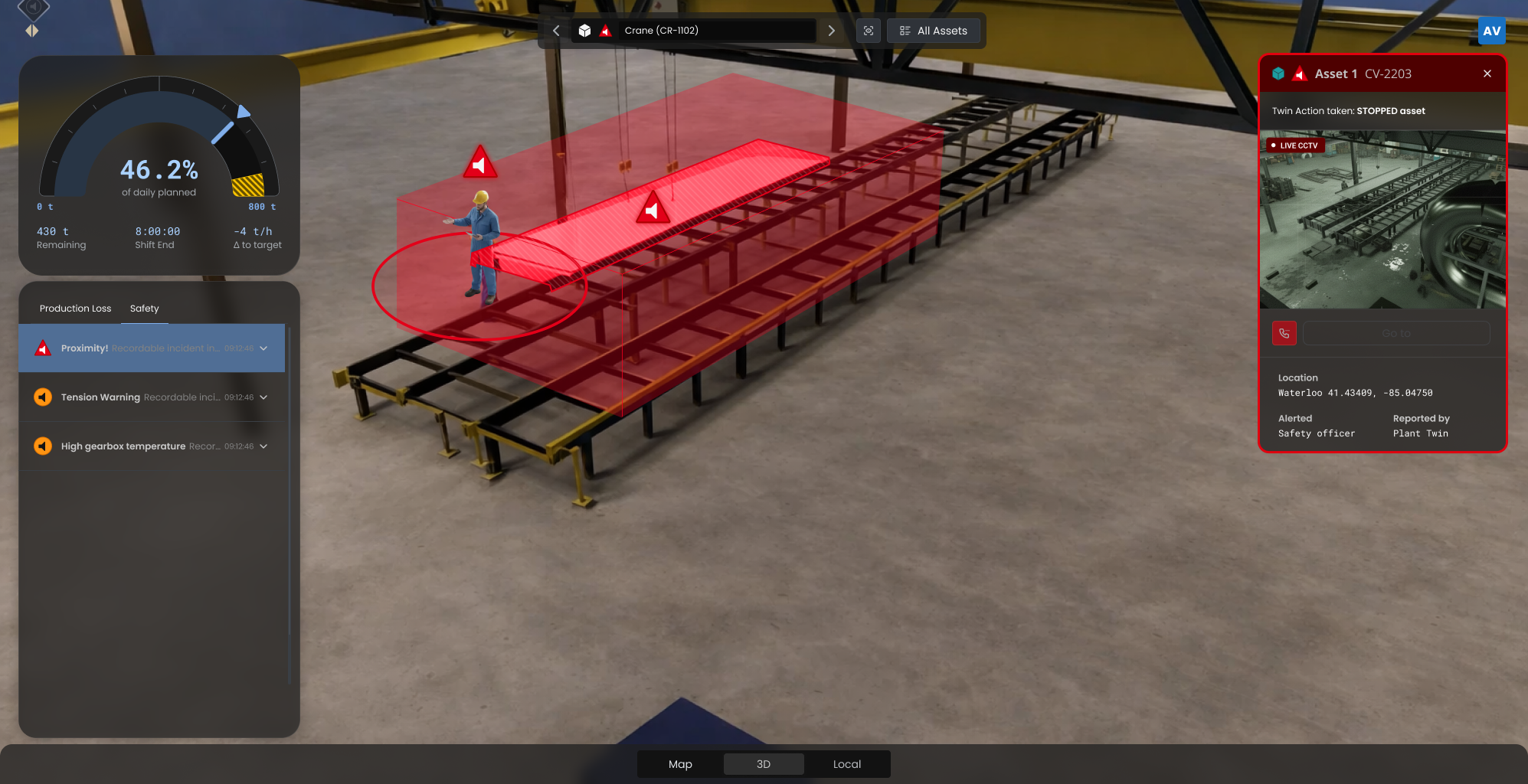

Manufacturing Site Twin

Focus 1: line stability, changeovers, downtime causes, maintenance deconfliction

Focus 2: safety in mixed traffic zones, overhead crane semi-autonomy

Documented first win: identification of exactly where waste is being created in process, and how ERP inventory tracking can be substantially improved

Key connected systems & plans: OT Historian/SCADA, CMMS/EAM, MES, ERP, Safety

Recycling Site Twin

Focus 1: feedstock variability (quality, type, timing), inbound-process-outbound constraints, yard congestion and rehandle

Focus 2: safety in mixed traffic, remote supervision of small sites, contamination/quality impacts

Documented first win: visibility of constraints along value chain drives development of “playbooks” for known feedstock variability

Key connected systems and plans: OT Historian/SCADA, CMMS, Delivery Schedules, Maintenance Plans, Safety

Why Choose Geminum?

We are operations, safety, maintenance and data experts who have chosen to specialise in digital twins for production intensive companies.

We are the team that develops, delivers & validates improved production, safety and maintenance outcomes you need to create truly integrated asset operations.