Site Twin

A digital twin platform that unifies and enhances Production, Safety and Maintenance, configured to maximise the value of existing systems and data.

A Site Twin requires no rip and replace. It sits over your existing systems, gives teams access to the right data in context (via browser and mobile), and links users back to the approved controls & systems of record to take action.

Core Features

Explore 3D - shared operational picture

Near real time 3D visualisation and playback of site operations, plans, movements and events so teams share the same context.

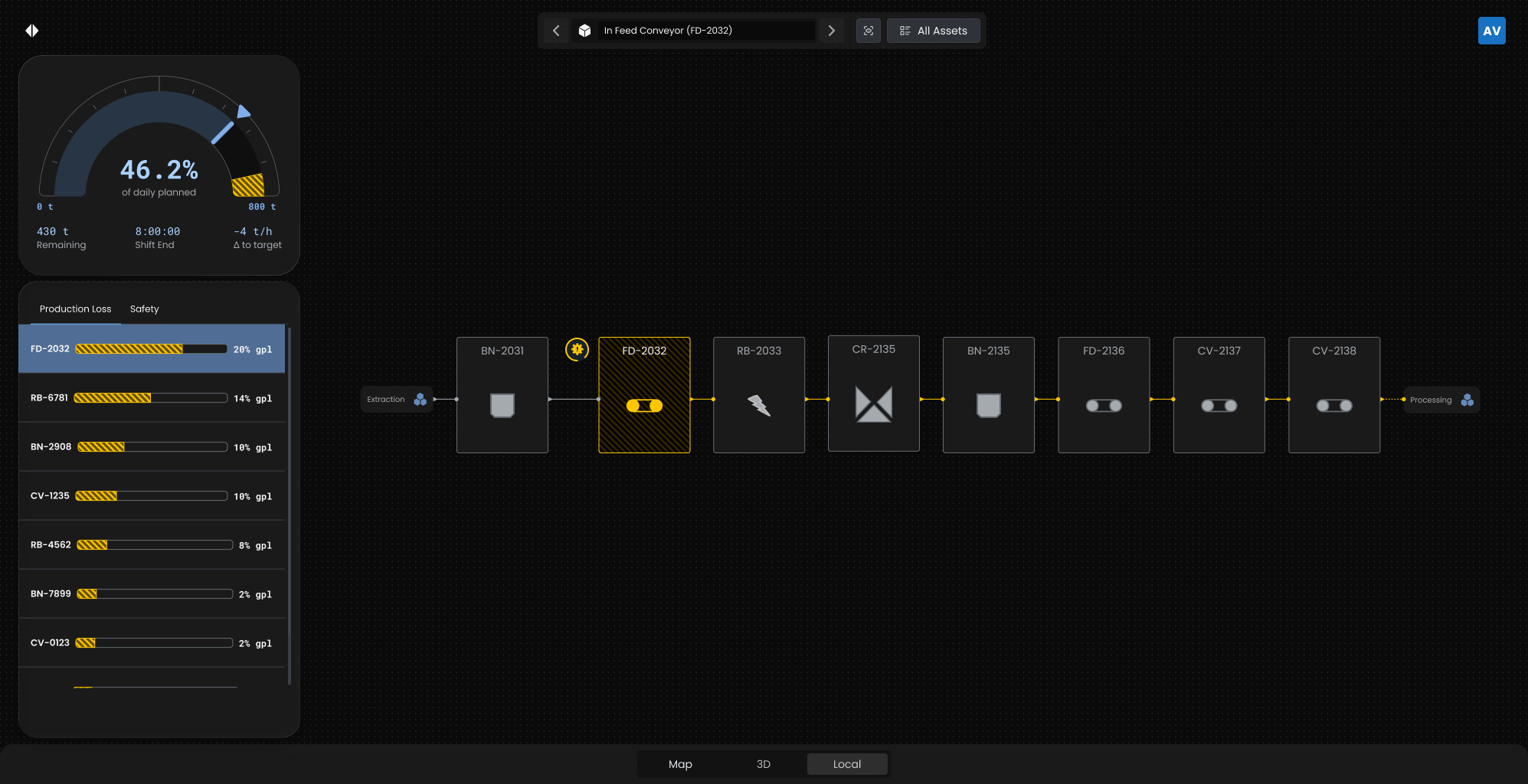

Value Chain - dynamic constraint model

Models the value chain and shows local vs global constraints, deltas to plan/capacity, and where losses are occurring.

Assets & Work - find what matters, fast

Unifies asset history, documents and work orders so maintainers and supervisors stop wasting time searching and can intervene faster.

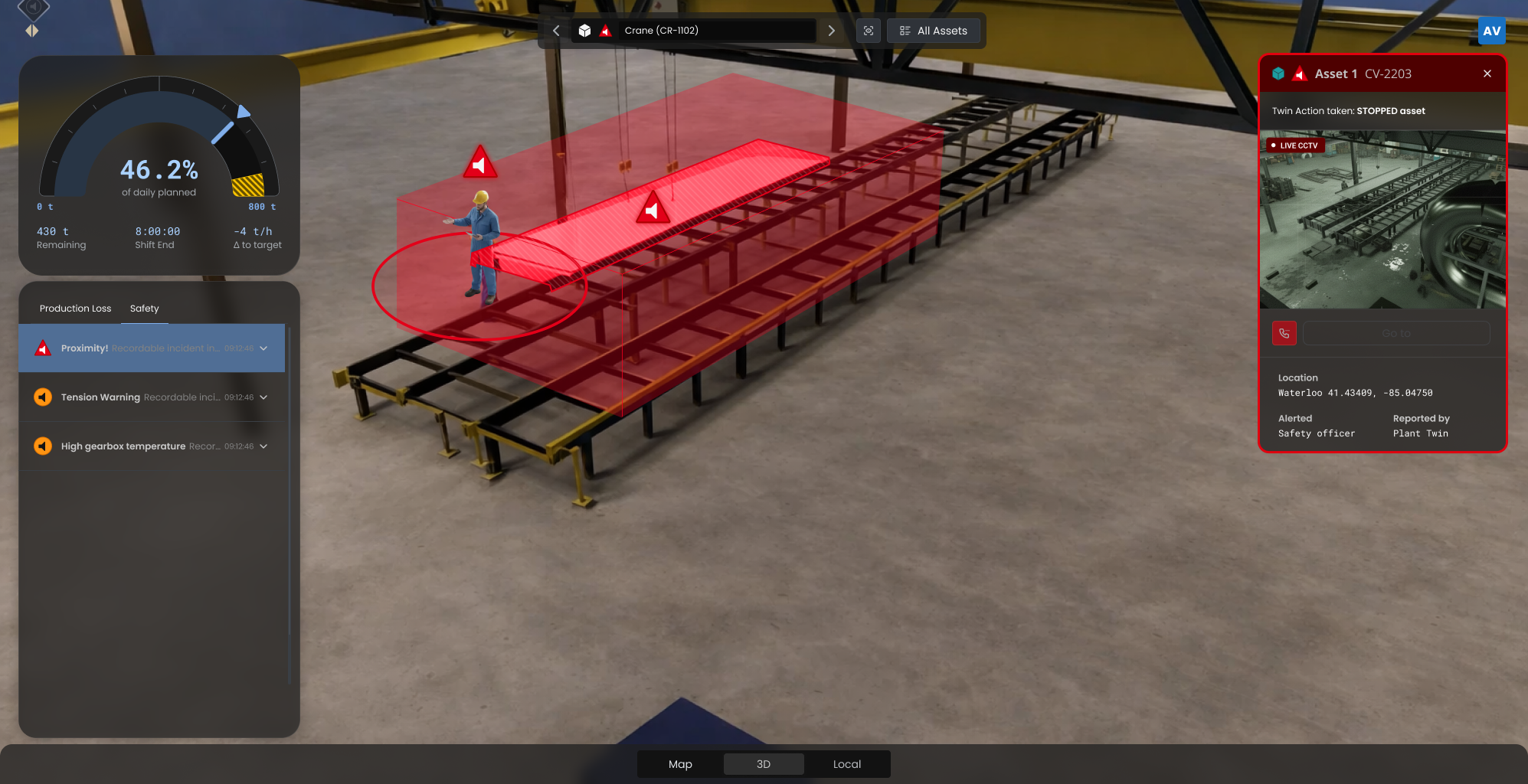

Persistent monitoring via cameras, LiDAR and AI, with escalation rules that surface risks, near misses and compliance issues without creating workflow noise.

Safety - monitor & escalate

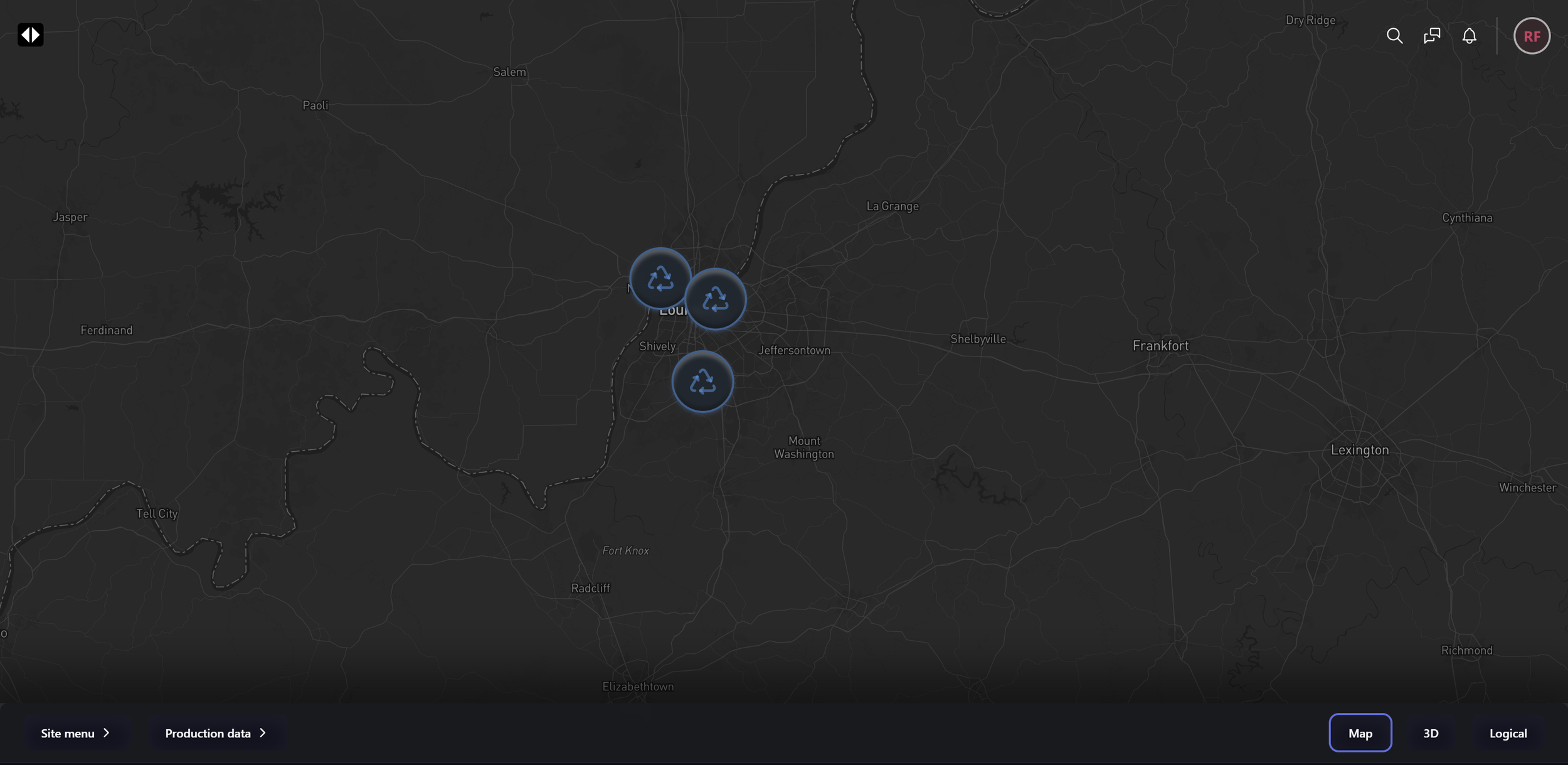

Roll up performance and issues across sites, benchmark asset classes across sites, drill down, and spread what works.

Portfolio - look across sites

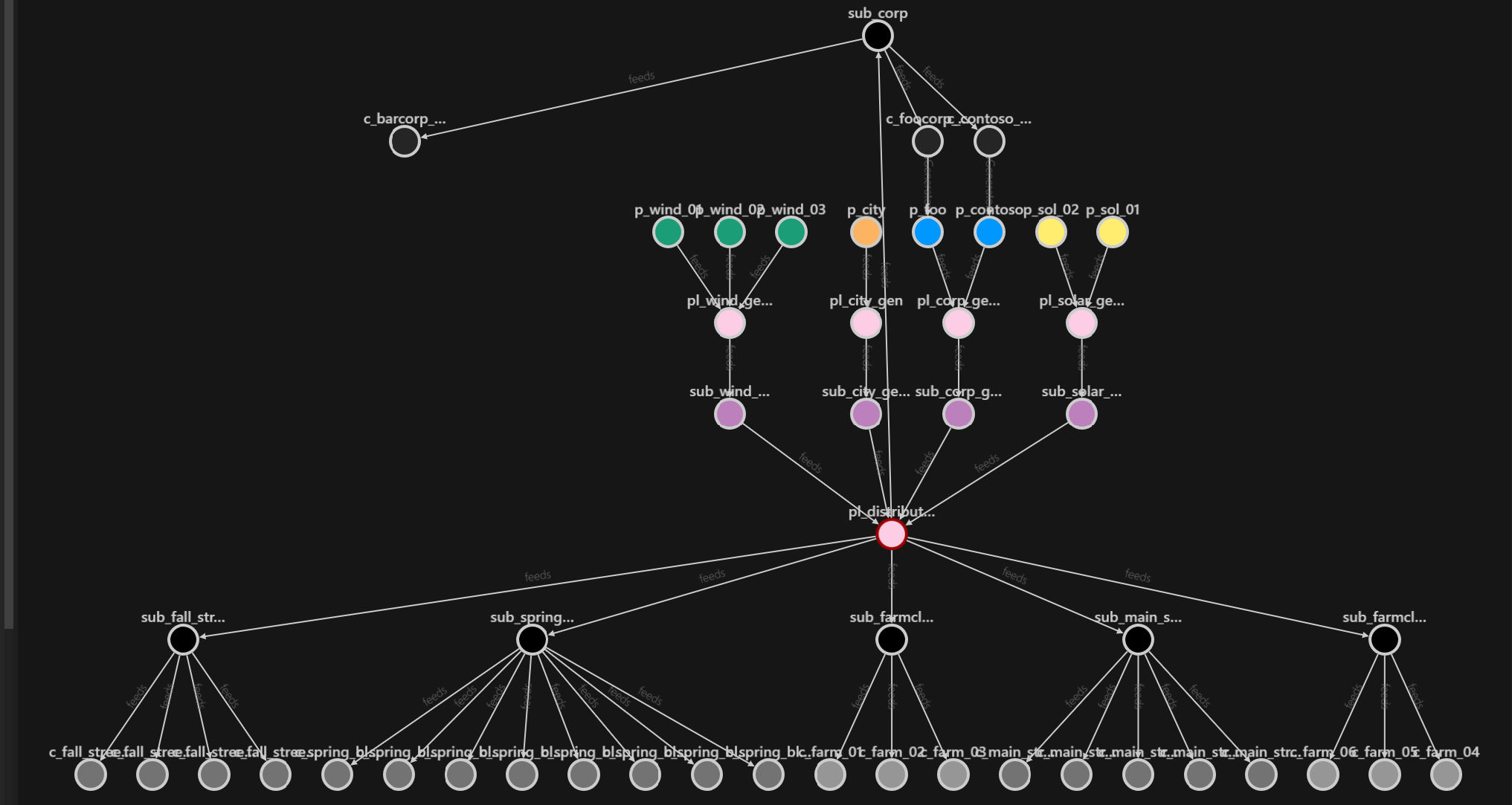

Create and track the state of events across your site, from every connected system and internal models (e.g. constraints and safety events). Relationships between Events and Assets enable contextual search and intelligent AI foundations.

Events & Relationships - global event tracking & graphs

How do you use it

Daily

See live and predicted constraints

See live ETAs and updates on supplier deliveries and product pickups

Collaborate with Safety in real time to mitigate or escalate issues

Raise or approve/decline automated production plan changes through connected systems or via Teams/WhatsApp

Collaborate with Maintenance in real time to solve live faults or re-schedule work

Production / Operations

Weekly / Monthly / Quarterly

Review production vs plan and production vs capacity performance

Playback constraints, faults and events in 3D and timeline to assess where performance was lost

Export all data to 3rd party systems for analysis and planning

Daily

See live and predicted Safety near misses and incidents

Playback safety near misses and incidents

Collaborate with Production & Maintenance in real time to mitigate or escalate issues

Raise or approve/decline automated Safety reports through connected systems or via Teams/WhatsApp

Safety

Weekly / Monthly / Quarterly

Review safety near misses and incidents vs fault, constraint and work history

Export 3D playbacks of Events

Export all data to 3rd party systems for investigation and reporting

Daily

See where faults and constraints are and have overlapped

Quickly find documents, asset and operational data, including faults, constraints and work history

Raise or approve/decline automated work orders (new or changes to existing) through connected EAM/CMMS

Collaborate with Production in real time to solve live issues

Maintenance & Engineering

Weekly / Monthly / Quarterly

Review fault, constraint and asset history to assign Improvement projects or alter Scheduled Work

Export all data to 3rd party systems for detailed analysis and root cause

End of Shift / Pre-start Review - Production, Safety & Maintenance Events & Constraints with 3D playbacks

Cross-functional

Shared Live 3D Situation Awareness - everyone can see the same Events & Constraints across Site and along the Value Chain

Collaboration & Reporting - Microsoft Teams chats on any Event or Constraint, with live 3D views and operational overlays.

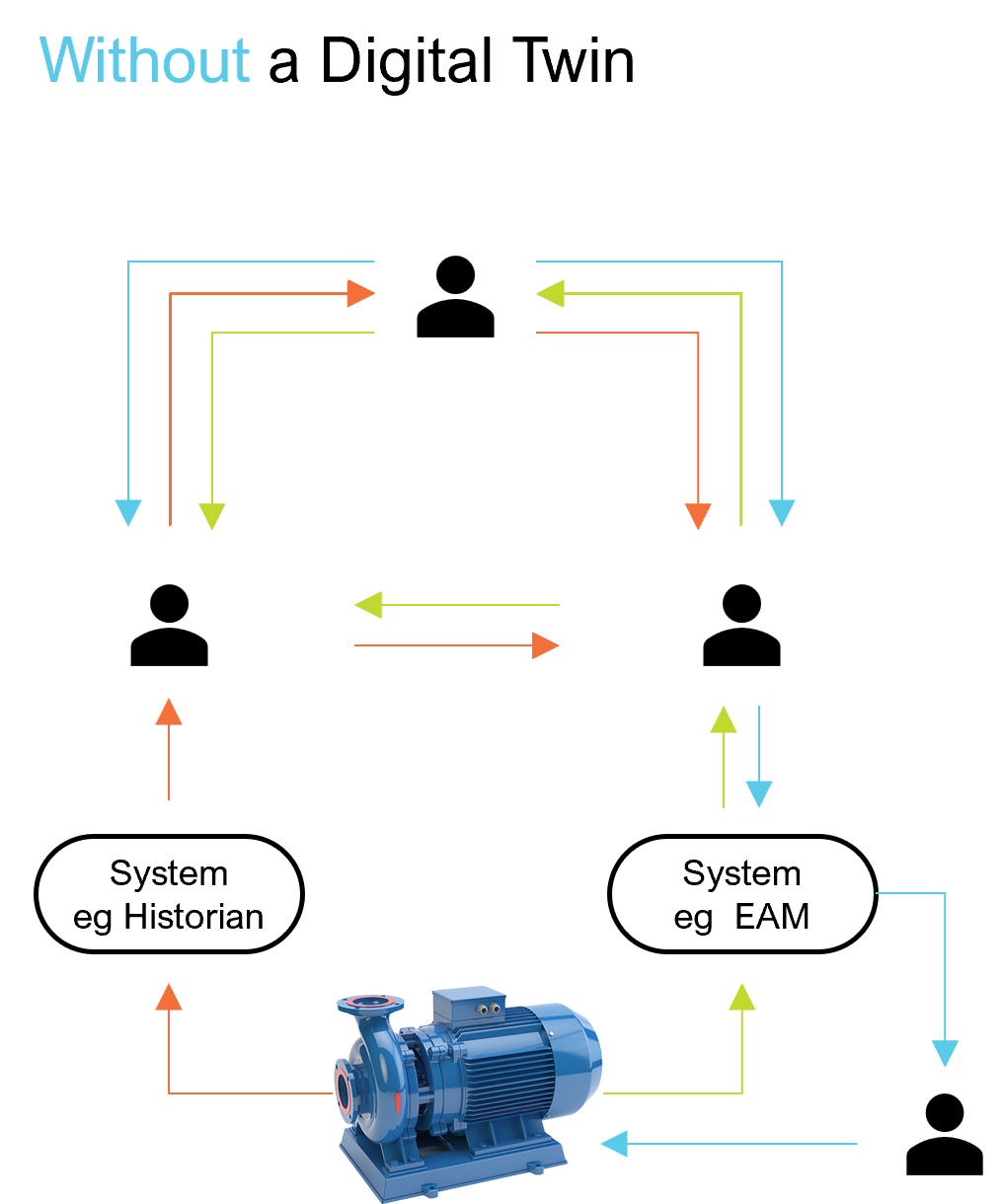

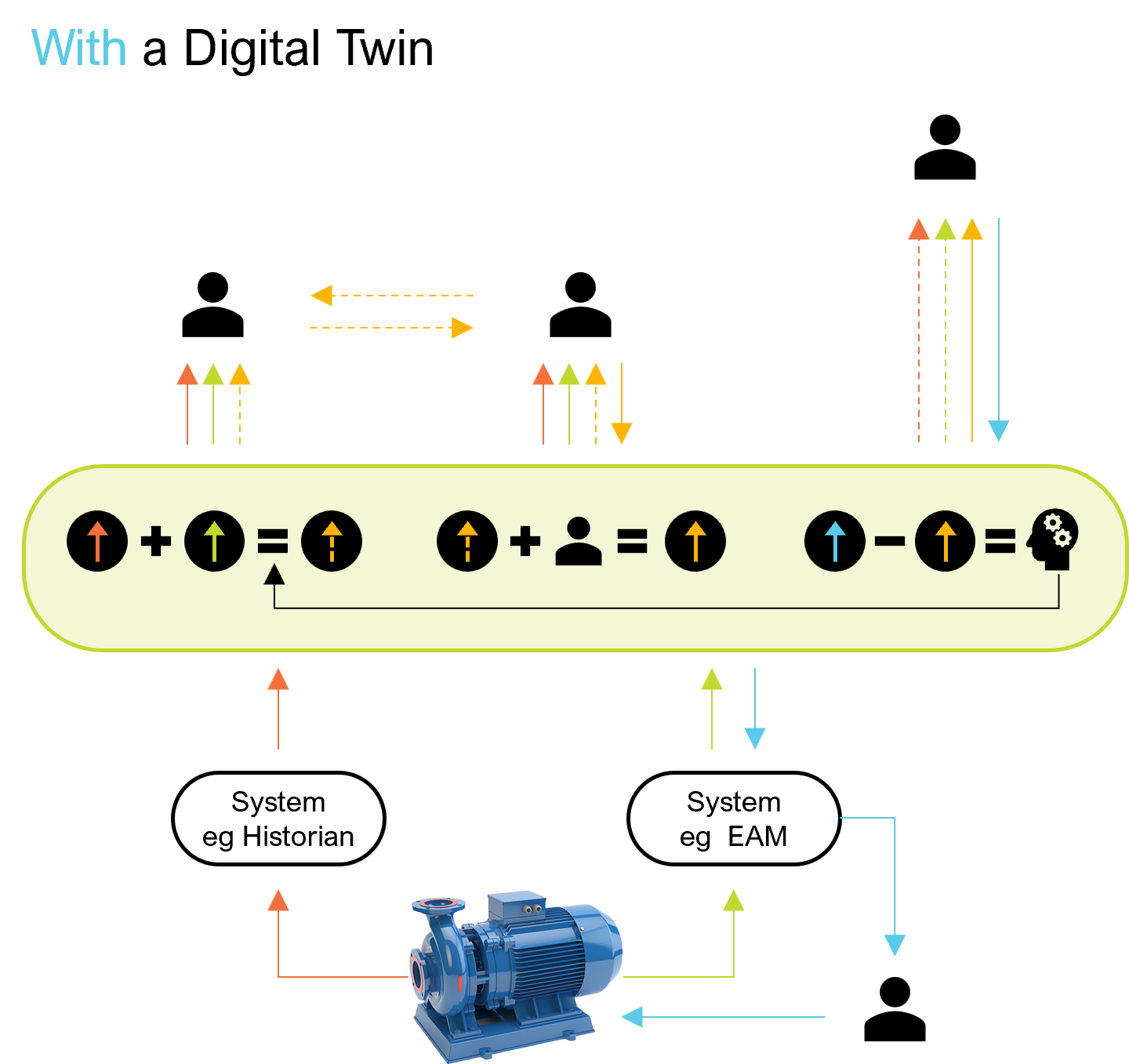

How it works

From (Connected) Data to (Informed) Decisions to (Rapid) Action

The Site Twin sits over connected systems and contains site specific data models

Connect OT/IOT and enterprise systems (SCADA/OT historian, EAM/CMMS, ERP/MES, GIS, fleet, safety systems, planning tools)

Transform and juxtapose data from connected silos to create high context for humans (3D & Geospatial with overlays) and AI (event graphs)

Push and record actions back into connected systems (work orders, setpoints, escalations, planning updates) and direct to other Deciders/Actors (humans & agents)

The Site Twin uses cloud and, where required, additional on-prem components (cameras, compute, storage) to support near real time decision support and action.

For sub-second safety interventions, on-prem compute and storage are required to avoid cloud latency and connectivity risk.

The Site Twin is available to unlimited users through any compatible browser. Mobile applications are commonly bundled.

Architecture & Scope

How do we Deliver

-

Assess Site processes, systems, data locations, constraints and objectives.

Deliver the Digital Twin Maturity & Readiness Assessment and clear next steps.

Typical duration 2–5 weeks.

-

Connect key systems for a single operational view. Start with constraint identification so teams align on where losses are occurring. Establish the event stream and embed Collaboration into daily/short-interval workflows.

Typical duration 12-16 weeks

-

Add causality and prediction to constraints, predictive maintenance, and persistent safety monitoring and escalation.

Where needed, co-specify extra comms/compute to support rapid interventions.

Typical duration 12-16 wks

-

Roll out complete Site Twin to other sites with lower cost and time using shared platform elements and learnings from Site 1.

Typical timing: 6 mths after rollout (i.e. measurable ROI)

-

Add new data sources, new agents, and new workflows as your operating model evolves and teams become more confident with AI and agentic workflows.

Typical timing: Driven by outcomes

Site Twins are delivered as a combined Services & Product offering

Diagnosis, Discovery, Delivery (inc Constraint Models), and Business Process Engineering are all delivered as Services.

Some Sites need a little, some need a lot.

Additional data (such as LIDAR/site scanning), Integrations and Procurement /Installation /Commissioning of hardware are all Managed Services (we mange the work, we don’t self-preform).

Some Sites perform this all themselves, some outsource all of it.

The Site Twin platform is our Product. It’s a SaaS service, priced based on value and risk.

Why Choose Geminum?

We are operations, safety, maintenance and data experts who have chosen to specialise in digital twins for production intensive companies.

We are the team that develops, delivers & validates improved production, safety and maintenance outcomes you need to create truly integrated asset operations.